LED headlamp bulbs have become a popular choice for modern vehicles due to their energy efficiency and superior brightness. However, one essential aspect of their design is often overlooked: the need for active cooling.

In this article, we’ll explore why active cooling is crucial for maintaining optimal performance and preventing overheating, ensuring your LED headlamps deliver long-lasting, reliable illumination. Therefore, we invite you to keep reading to discover the science behind it and what it means for your vehicle’s lighting system.

So, without further ado, let’s get started…

What Are LED Headlamp Bulbs?

LED headlamp bulbs are a type of automotive lighting that use light-emitting diodes (LEDs) to illuminate the road ahead. Unlike traditional halogen or incandescent bulbs, LED bulbs are more energy-efficient, produce less heat, and have a longer lifespan. They work by passing electrical current through a semiconductor, causing it to emit light.

Key features of LED headlamp bulbs:

- Brightness: LEDs provide a bright, white light that enhances visibility, often closer to daylight than halogen bulbs.

- Energy Efficiency: LED bulbs use less power, making them more energy-efficient, which can benefit the car's electrical system.

- Durability: LED bulbs are designed to last longer, often up to 25,000 hours or more, reducing the need for frequent replacements.

- Heat Management: They produce less heat than halogen bulbs, which can prevent damage to surrounding components.

- Instant On: LED headlights light up instantly when turned on, unlike some other types of bulbs that may take time to reach full brightness.

Nowadays, LED headlamps are becoming increasingly popular due to their performance, longevity, and energy savings. Furthermore, they are commonly found in both modern vehicles and aftermarket upgrades.

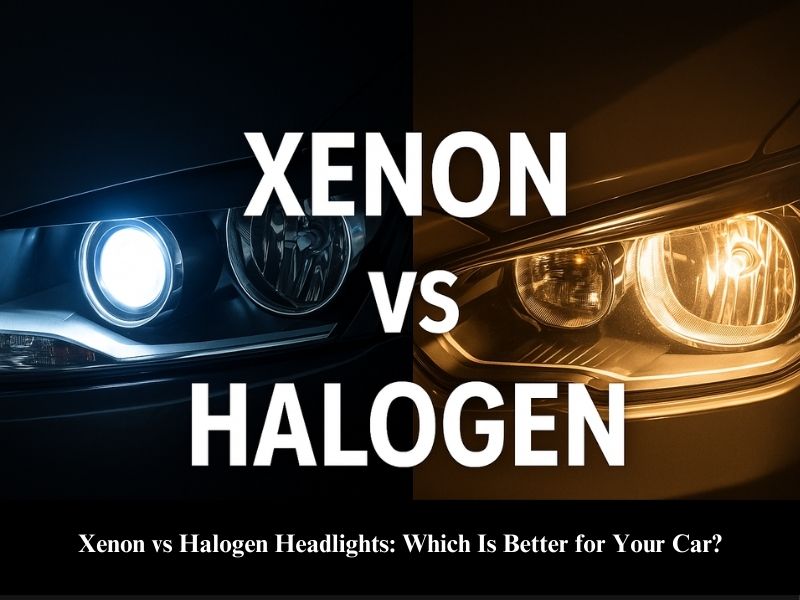

How LED Headlamp Bulbs Differs from Halogen and Xenon Lights?

Here’s how led headlamp bulbs differs from halogen and xenon lights:

1. LED Technology:

As we discussed before, LEDs are solid-state lights that work by passing electricity through a semiconductor, which produces light. The key benefits of LED lighting in automotive applications include:

- Energy Efficiency: LEDs require significantly less energy compared to halogen and xenon bulbs, which reduces the load on a vehicle’s electrical system.

- Instant Illumination: Unlike some traditional bulbs, LEDs light up instantly when powered, offering immediate full brightness.

- Cooler Operation: LEDs emit far less heat than halogen or xenon lights, reducing the risk of heat-related damage to headlamp components.

- Durability: LED bulbs are highly resistant to vibrations, impacts, and harsh conditions, making them more robust for automotive use.

2. Halogen Bulbs:

Halogen bulbs are the most common type of headlamp technology used in vehicles. They work by heating a tungsten filament inside a glass bulb filled with halogen gas. The filament heats up and emits light when electricity flows through it.

While affordable and simple to manufacture, halogen bulbs have several disadvantages compared to LED:

- Energy Consumption: Halogen bulbs consume more power than LEDs, reducing vehicle fuel efficiency.

- Shorter Lifespan: Halogen bulbs typically last around 1,000 to 5,000 hours, much shorter than LED headlamps.

- Heat Emission: Halogen bulbs produce a significant amount of heat, which can cause degradation of headlight housing over time.

3. Xenon (HID) Bulbs:

Xenon bulbs, also known as high-intensity discharge (HID) bulbs, create light by passing an electrical current through a xenon gas-filled bulb.

It’s true that they produce a bright, blue-white light, offering high visibility, but have limitations compared to LED technology:

- Energy Use: Xenon lights are more energy-efficient than halogens but still consume more power than LEDs.

- Startup Time: Xenon bulbs may require a few seconds to reach full brightness, unlike LEDs which provide instant illumination.

- Heat and Durability: Xenon bulbs run hotter than LEDs and are more susceptible to vibrations, which can shorten their lifespan.

Common Applications of LED Headlamp Bulbs in Automotive Lighting

LED headlamps are widely used in various applications within automotive lighting, offering improved safety, style, and performance. Here are some of the common applications of LED headlamp bulbs in automotive lighting:

- Headlights (Low and High Beam): LEDs are commonly used in vehicle headlights, providing clearer and brighter lighting that improves visibility during nighttime driving and in poor weather conditions.

- Daytime Running Lights (DRLs): Many modern vehicles incorporate LED DRLs, which enhance a car’s visibility during the day while consuming minimal power.

- Fog Lights: LED fog lights are favored for their ability to cut through fog, rain, and snow with focused, bright light.

- Tail Lights and Brake Lights: LEDs are used for rear lighting, offering faster response times, which improves safety as brake lights illuminate quicker than traditional bulbs.

- Turn Signals and Indicators: LED turn signals provide bright, sharp illumination, making vehicles more noticeable to other drivers.

- Interior and Accent Lighting: Inside vehicles, LED lights are used for dashboard lighting, dome lights, and ambient accent lighting to enhance the cabin's look and functionality.

The Heat Generation Problem In LED Headlamp Bulbs

While LED bulbs are known for their energy efficiency and longevity, they do generate some heat during operation. Therefore, it's important to understand how this heat is produced and how it compares to other bulb types to evaluate the performance and safety of automotive lighting systems effectively.

How LED Bulbs Generate Heat?

LED bulbs produce light through a process called electroluminescence, where an electrical current passes through a semiconductor material. While doing this process, there are instances where that can generate considerable amount of heat which could harm the LED headlamp bulbs.

Here’s how heat generation occurs in LED bulbs:

- Electrical Resistance: When current flows through the LED, not all the energy is converted to light. Some energy is lost as heat due to electrical resistance in the semiconductor material.

- Heat Sink Requirement: To manage the heat produced, most LED headlamps are equipped with heat sinks. These components dissipate heat away from the LED, maintaining optimal operating temperatures and preventing overheating.

- Thermal Management: Effective thermal management is critical in LED design to ensure longevity and performance. Poor heat dissipation can lead to decreased light output, color shifts, and shortened lifespan.

Temperature Sensitivity Of LED Headlamp Bulbs

Although LEDs are known for their energy efficiency and low heat output, they are still sensitive to temperature. Furthermore, excessive heat can negatively affect their performance and longevity.

Here is a further explanation on temperature sensitivity of LEDs:

- The efficiency of LEDs is closely tied to the temperature of the semiconductor material. As the temperature increases, the performance of the LED can degrade, leading to reduced light output (lumen depreciation) and color shifts.

- If the LED temperature exceeds optimal operating conditions, it can enter a state known as thermal runaway, where increased heat leads to further efficiency losses, creating a cycle that can damage the chip permanently.

- Most LED chips have a specified operating temperature range. Excessive heat can push them beyond this range, resulting in failure or dramatically reduced performance.

Impact of Excessive Heat on Performance and Lifespan

- Reduces Brightness: High temperatures can lead to decreased lumen output, making the light dimmer and less effective for visibility.

- Color Shift: Heat can alter the color temperature of the LED, causing a shift from the desired cool white light to a warmer or yellowish tone.

- Shortened Lifespan: LEDs typically have a lifespan of 20,000 to 50,000 hours under ideal conditions. However, excessive heat can drastically reduce this lifespan, sometimes leading to failure in as little as a few thousand hours.

Comparison of Heat Output Between LED, Halogen, and Xenon Headlamp Bulbs

Understanding the heat output of different bulb types can help in selecting the most suitable lighting technology for vehicles.

1. LED Bulbs:

- Heat Output: LEDs produce significantly less heat compared to halogen and xenon bulbs. Approximately 20-30% of the energy consumed is converted into light, with the remainder dissipated as heat.

- Efficiency: High efficiency leads to lower heat generation, making LEDs cooler to the touch after prolonged use.

2. Halogen Bulbs:

- Heat Output: Halogen bulbs generate a considerable amount of heat, with around 80% of the energy consumed converted into heat rather than light. This high heat output is a primary reason for their shorter lifespan and the potential for heat damage to headlight housings.

- Operating Temperature: Halogen bulbs can reach high operating temperatures, which can be hazardous if they come into contact with flammable materials.

3. Xenon (HID) Bulbs:

- Heat Output: Xenon bulbs produce less heat than halogen bulbs but more than LEDs. About 30-40% of the energy is emitted as heat, with the rest converted to light.

-

Startup Heat: Xenon bulbs can generate a significant amount of heat during their initial startup phase, although they do operate cooler than halogen bulbs once at full brightness.

|

Bulb Type

|

Heat Output (%)

|

Characteristics

|

|

LED

|

20-30%

|

Low heat generation; efficient; requires effective thermal management.

|

|

Halogen

|

80%

|

High heat generation; lower efficiency; can damage housing due to high temperatures.

|

|

Xenon (HID)

|

30-40%

|

Moderate heat generation; cooler than halogen but generates significant heat at startup.

|

[Summary of Heat Output]

Mechanisms Available For Heat Dissipation in LED Headlamp Bulbs

Effective heat dissipation is critical in ensuring the performance and longevity of LED headlamp bulbs. As LEDs generate heat during operation, various mechanisms are employed to manage this heat and prevent thermal damage.

The following are the primary mechanisms available for heat dissipation in LED headlamp bulbs:

1. Passive Cooling Methods

These passive cooling methods do not require any external power or mechanical components and rely on natural heat dissipation processes. There are mainly 3 types, such as heat sink, thermal interface materials, convection, of passive cooling methods that could help in cooling down LED chips.

Here is a further explanation those terms:

a. Heat Sinks:

Heat sinks are typically made from high thermal conductivity materials, such as aluminum or copper. They are designed with fins or extended surfaces to increase the area available for heat dissipation.

- Function: The heat sink absorbs heat generated by the LED chips and dissipates it into the surrounding air through convection. The larger the heat sink, the more effective it is at reducing temperatures.

b. Thermal Interface Materials (TIMs):

TIMs are materials placed between the LED chip and the heat sink to enhance thermal conductivity.

- Function: They fill microscopic gaps between surfaces, improving heat transfer from the LED to the heat sink.

c. Convection:

This is the natural movement of air that helps remove heat from the LED bulb.

- Function: As air around the heat sink heats up, it rises and is replaced by cooler air, facilitating heat dissipation without the need for fans or additional energy.

2. Active Cooling Methods

Active cooling methods use mechanical components to enhance heat dissipation. Here are some of the most commonly used active cooling methods that use to solve LED headlight bulbs overheating issues.

i. Cooling Fans:

Small electric fans may be integrated into the headlamp design to increase airflow around the LED bulbs.

- Function: Fans actively blow air over the heat sink, improving heat exchange and accelerating the cooling process. This method can be particularly effective in high-performance or high-intensity applications where heat generation is significant.

ii. Liquid Cooling Systems:

Although less common in automotive applications, some advanced LED systems utilize liquid cooling.

- Function: Liquid cooling systems circulate coolant through channels or tubes in close proximity to the LED chips, effectively carrying heat away. This method can provide exceptional heat management but is more complex and expensive.

iii. Thermoelectric Coolers (TECs):

TECs are solid-state devices that create a heat flux between the junctions of two different materials when an electric current is applied.

- Function: They can be used to actively cool LED components by transferring heat away from the LED chip. While effective, TECs require additional power and can add complexity to the design.

Benefits of Active Cooling in LED Headlamp Bulbs

Active cooling systems are crucial for maintaining the performance and longevity of LED headlamp bulbs, especially in high-demand automotive applications. Here are the key benefits of integrating active cooling into LED lighting systems:

1. Prevention of Overheating

- Effective Heat Dissipation: Active cooling, such as small fans or advanced thermal interface materials, helps dissipate heat away from the LED chips more efficiently than passive methods. This prevents the temperature from reaching dangerous levels that could degrade performance.

- Maintaining Optimal Operating Temperature: Active cooling keeps the LED bulbs operating within their ideal temperature range, ensuring consistent brightness and output, even during prolonged use.

2. Extended Lifespan

- Reduced Thermal Stress: By keeping temperatures low, active cooling systems prevent thermal stress on the LED components. This directly contributes to an extended operational lifespan, potentially reaching 20,000 to 50,000 hours.

- Minimized Degradation: Excessive heat accelerates the degradation of LED materials and electronic components. Active cooling helps preserve these materials, reducing wear and ensuring that the bulbs remain effective for longer periods.

3. Improved Performance and Brightness

- Consistent Light Output: LEDs produce optimal light output when operating at lower temperatures. Active cooling prevents brightness loss caused by overheating, maintaining high luminous efficacy and ensuring that drivers have the visibility they need.

- Enhanced Efficiency: LEDs are known for their efficiency, but without proper cooling, that efficiency can decline. Active cooling helps maintain the energy-efficient nature of LEDs, ensuring they convert as much electrical power into light as possible rather than heat.

Comparison: Fan vs. Fanless LED Headlights

When it comes to cooling mechanisms for LED headlights, there are two primary approaches: fan-based (active cooling) and fanless (passive cooling) designs. Each has its advantages and drawbacks, which can affect performance, reliability, and design flexibility.

1. Fan-Based (Active Cooling) LED Headlights

Fan-based LED headlights use small built-in fans to actively dissipate heat from the LED chips. The fans increase airflow over the heat sink or LED housing, allowing heat to escape faster.

Advantages:

- Superior Heat Dissipation: The fans provide effective, high-capacity cooling, allowing LED headlights to run at higher power levels without overheating. This is crucial in high-performance or high-output LED systems.

- Optimal for High-Power LEDs: Fan-based systems are ideal for more powerful LEDs that produce significant heat, as the fan can handle the higher thermal load.

- Longer Lifespan for LEDs: By actively managing heat, fan-based headlights help prevent thermal damage and extend the overall lifespan of the LED components.

Disadvantages:

- Moving Parts and Reliability: The inclusion of a fan introduces moving parts, which can wear out over time, reducing the reliability of the cooling system. Fans are also susceptible to dust or debris, which can affect their function.

- Noise: Some fan-based LED headlights can generate noise, especially in lower-quality designs. While usually minimal, it may be noticeable in very quiet environments.

- Larger Form Factor: Due to the additional components (fan and housing), fan-based systems tend to be bulkier and may be harder to fit into tight headlamp housings.

2. Fanless (Passive Cooling) LED Headlights

Fanless LED headlights rely on passive cooling methods, typically large heat sinks or braided copper/aluminum cooling strips, to dissipate heat through natural convection and conduction.

Advantages:

- No Moving Parts: Since fanless LED headlights rely on passive cooling, they have no moving parts that could wear out or fail, offering better reliability in the long term.

- Silent Operation: Fanless designs are completely silent, making them ideal for applications where noise is a concern, though this is often not a major issue in automotive applications.

- Smaller and More Compact: Fanless designs are often more compact, making them easier to install in vehicles with limited space for headlamp components.

- Less Maintenance: Without fans, there is less risk of dust or debris interfering with the cooling system, reducing the need for regular cleaning or maintenance.

Disadvantages:

- Lower Heat Dissipation Capacity: Fanless headlights typically have lower heat dissipation capabilities compared to fan-cooled systems. This makes them less suitable for high-output LED bulbs that generate more heat.

- Limited Power Output: To avoid overheating, fanless LED headlights often operate at lower power outputs, which can limit their brightness compared to their fan-based counterparts.

- Potential for Reduced Lifespan: In some cases, the lack of active cooling can lead to higher temperatures, especially in tightly enclosed spaces, potentially reducing the lifespan of the LEDs if not properly managed.

|

Aspect |

Fan-Based LED Headlights |

Fanless LED Headlights |

|

Cooling Method |

Active (Fan for airflow) |

Passive (Heat sink, cooling strips) |

|

Heat Dissipation Capacity |

High, suitable for high-power LEDs |

Moderate, better for lower-power LEDs |

|

Lifespan |

Longer, but dependent on fan reliability |

Typically long due to no moving parts |

|

Noise |

Can be slightly noisy (depending on fan) |

Silent operation |

|

Reliability |

More prone to failure due to moving parts |

More reliable due to lack of moving parts |

|

Installation Space |

Bulky, needs more space for the fan assembly |

More compact, easier to install in tight areas |

|

Maintenance |

May need cleaning due to dust in the fan |

Low maintenance, no risk of fan clogging |

|

Power Output |

Can handle high power, brighter light output |

Typically lower power, less bright |

[Comparison Summary]

When to Choose Fan-Based vs. Fanless

Choose Fan-Based LED Headlights If:

- You need high-performance, high-output lighting with maximum brightness.

- You require excellent heat management for intense driving conditions (off-roading, long drives, extreme climates).

- You don't mind potential noise or bulkier design in exchange for better performance.

Choose Fanless LED Headlights If:

- You prioritize reliability and don’t want to worry about mechanical parts failing.

- You prefer a compact, silent design that’s easier to install in smaller spaces.

- You’re using LEDs in standard conditions where extreme heat dissipation is not critical.

Related Articles

- Top 12 Tips to Find the Best LED Headlights for Your Vehicle in 2024

- How to Install LED Headlight Bulbs: Quick & Simple

- LED Lighting for the Next Wave of Electric Cars

- How to Extend the Life of Your Car Headlights?

- Are LED headlights safe?

Where to Buy the Best LED Headlamp Bulbs in 2024

Ready to enhance your vehicle's headlights with high-performance LED headlamp bulbs? At Carifex, we provide a comprehensive selection of the latest LED lighting solutions tailored for a variety of vehicles, including LED Headlights, LED Tail Lights, LED Fog Lights, and many more.

Here’s why Carifex is your top choice for LED headlamp bulbs:

- Quality Assurance: Our LED headlamp bulbs adhere to rigorous quality standards, ensuring dependable and long-lasting performance whether you're on the highway or navigating off-road terrain.

- Wide Selection: We offer a diverse range of designs and styles to complement your vehicle's aesthetics while fulfilling your lighting needs.

- Competitive Pricing: Benefit from great value with our affordable pricing, making it easy to upgrade your vehicle’s lighting system without breaking the bank.

- Customer Satisfaction: Our dedicated team is committed to providing outstanding customer service, helping you choose the ideal product and offering support with installation.

Explore our range of headlights and other LED automotive products today. Click below to visit our store and discover the perfect upgrades for your vehicle!

Final Thoughts

Active cooling is essential for maintaining the performance and longevity of LED headlamp bulbs, as it effectively manages the heat they generate. LEDs, despite their energy efficiency, can still produce enough heat to degrade performance if not properly dissipated.

Furthermore, keep in mind that fan-based active cooling systems and passive heat sinks both play a critical role in preventing overheating, preserving brightness, and extending bulb lifespan.

Overall, choosing an LED headlamp with an efficient cooling mechanism ensures not only better lighting but also long-term reliability for your vehicle’s lighting system.

Key Points

- LED headlamp bulbs, while energy-efficient and long-lasting, generate heat during operation, which requires effective cooling to prevent performance degradation and extend lifespan.

- Active cooling mechanisms, like fans or liquid cooling, are essential to manage the heat generated by LEDs, as poor heat dissipation can lead to color shifts, reduced brightness, and shorter bulb life.

- LEDs emit significantly less heat than halogen and xenon bulbs, making them more energy-efficient and durable, but they are still sensitive to temperature fluctuations.

- High temperatures can cause lumen depreciation (reduced brightness), color shifts, and shorten the lifespan of LED bulbs, making proper cooling mechanisms essential for optimal performance.

- Passive cooling methods like heat sinks and convection can be sufficient for standard applications, but active cooling (e.g., fans or thermoelectric coolers) is necessary for high-performance or intense use scenarios.

- Active cooling prevents overheating, maintains optimal operating temperatures, and helps preserve LED brightness and performance, contributing to a longer operational lifespan.

- LED headlamp bulbs with fan-based active cooling systems offer better heat dissipation compared to fanless models, making them ideal for high-performance vehicles or extreme conditions.

- LEDs are widely used for headlights, daytime running lights, fog lights, and turn signals due to their brightness, energy efficiency, and faster response time compared to traditional bulbs.

FAQs

1. What causes LED headlamp bulbs to overheat?

LED headlamp bulbs generate heat primarily due to the LED chip and the electronic components that regulate power. If this heat isn't effectively dissipated, it can lead to overheating, reduced light output, and even bulb failure.

2. How does active cooling work in LED headlamps?

Active cooling typically involves a small fan or other mechanisms that circulate air around the heatsink of the LED bulb. This helps to continuously remove hot air and maintain optimal operating temperatures.

3. What are the benefits of using active cooling in LED headlamp bulbs?

Active cooling provides several benefits including consistent light output, color stability, longer lifespan, and improved reliability under various conditions.

4. Are there alternatives to active cooling for LED headlamps?

Yes, there are passive cooling solutions like heatsinks, but they may not be as effective in managing heat compared to active cooling systems, especially in high-performance applications.

5. What should I consider when choosing LED headlamp bulbs with active cooling?

Consider factors such as the quality of the cooling system, noise levels from fans, and compatibility with your vehicle's headlamp housing.

6. Do fanless LED headlamp bulbs perform as well as those with fans?

Fanless LED bulbs can be effective but may not dissipate heat as quickly as those with active cooling systems. They often have a longer lifespan due to fewer moving parts but might require regular maintenance to check the condition of heatsinks.

7. Can overheating affect the color output of LED headlamps?

Yes, excessive heat can cause color shifting in LED bulbs, leading to inconsistent light color. Active cooling helps maintain stable color temperatures by preventing overheating.

8. How do I know if my LED headlamp bulbs need active cooling?

If you notice dimming light output or color shifts over time, it may indicate that your bulbs are overheating and would benefit from an active cooling solution.