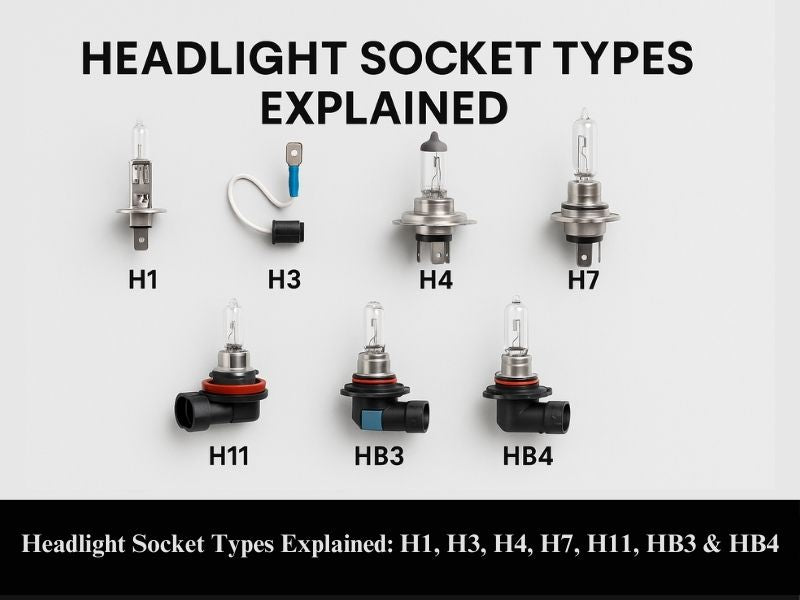

When it comes to vehicle lighting, understanding the different headlight socket types is crucial for proper installation and performance. With various options available, such as H1, H3, H4, H7, H11, HB3, and HB4, it can be challenging to know which one suits your vehicle best.

In this article, we'll break down the most commonly used headlight socket types, explaining their design, features, and applications. Whether you're replacing a bulb or upgrading your vehicle's lighting system, read on to find the right socket type for your needs!

What Is a Headlight Socket?

A headlight socket is a small but essential part of your vehicle’s lighting system. It acts as the connecting point between the car’s wiring harness and the headlight bulb, allowing power to flow to the bulb so it can light up properly.

Here’s what the headlight socket does:

-

Secure Connection: It holds the headlight bulb firmly in place.

-

Power Transfer: It delivers electrical current from the wiring harness to the bulb.

-

Stable Performance: It ensures a consistent and stable connection, which helps maintain steady headlight operation without flickering or failures.

-

Protection: Some sockets also help protect the bulb's base from moisture, dust, and vibration.

In simple terms, without a properly working headlight socket, the bulb won't receive power, meaning your headlights could fail to light up at all. That’s why it’s important to make sure the socket is compatible with your bulb type and remains in good condition.

What Are The Headlight Socket Types That Are Commonly Used In The Present Day?

When it comes to vehicle headlights today, a handful of socket types have become the standard across most car models. These socket types are designed to fit specific bulb styles, ensuring a secure connection and reliable performance.

The most commonly used headlight socket types are:

-

H1

-

H3

-

H4

-

H7

-

H11

-

HB3 (9005)

-

HB4 (9006)

These socket types are widely recognized and used in many makes and models around the world. Whether it's a sedan, SUV, or truck, manufacturers typically stick to these standardized sockets to simplify replacement and maintenance.

Each of these sockets has its own design, features, and purpose, making it important to choose the right one for your specific vehicle needs.

Now, let’s take a closer look at what makes each headlight socket type unique.

Detailed Breakdown of Each Headlight Socket Type

Now that you know the most common headlight socket types, it’s time to dive into the specifics. Each socket has unique features and applications, making it important to choose the right one for your vehicle.

Below, we’ll explore each socket type in detail to help you understand its design, uses, and key characteristics.

H1 Socket

The H1 socket is one of the most common types found in vehicle headlights today. It is designed to fit H1 bulbs, which are known for their strong, focused beam. H1 sockets are widely used for single-beam applications, providing either high beam or low beam lighting depending on the vehicle setup.

Design:

-

Single filament.

-

Slim, compact shape with a P14.5s base.

-

One prong terminal for electrical connection.

Common Uses:

-

High beam headlights.

-

Low beam headlights (in single-beam systems).

-

Fog lights (in some vehicles).

Features:

-

Provides a bright and concentrated beam pattern.

-

Compact size makes it easy to fit into tight headlight housings.

-

Simple, one-terminal design allows for straightforward installation.

Vehicles Commonly Using This Socket:

-

Many European cars (such as Audi, BMW, and Mercedes-Benz).

-

Some American and Japanese vehicles also use H1 sockets for high beams.

Important Notes:

-

Always check if your vehicle requires an H1 bulb before replacement, as the socket will only fit H1-specific bases.

-

When upgrading to LED or HID systems, you may need an adapter to fit H1 sockets properly.

H3 Socket

The H3 socket is built to fit H3 bulbs, which are commonly used in auxiliary lighting applications. It is a popular choice for vehicles needing strong, focused light in specific driving conditions like fog or off-road environments. H3 sockets are known for their unique wire lead attached directly to the bulb.

Design:

-

Single filament.

-

Compact design with a PK22s base.

-

Wire lead connection instead of standard prong terminals.

Common Uses:

-

Fog lights.

-

Driving lights.

-

Off-road auxiliary lights.

Features:

-

Direct wire connection ensures a secure and reliable power transfer.

-

Compact size for easy fitment in smaller or custom housings.

-

Strong light output, making it ideal for low-visibility conditions.

Vehicles Commonly Using This Socket:

-

Various SUV and off-road models.

-

Some older European and Japanese sedans for fog lights.

Important Notes:

-

The attached wire must be properly insulated and connected to avoid electrical shorts.

-

Some aftermarket LED and HID kits for H3 may require minor modifications to the socket or wiring.

H4 Socket

The H4 socket is designed for dual-filament bulbs, allowing a single bulb to serve both high beam and low beam functions. It is a common choice in many vehicles due to its versatility and reliable performance. H4 sockets are well-known for their three-prong design, which supports the dual function.

Design:

-

Dual filament.

-

Round base with a P43t type.

-

Three prongs for ground, low beam, and high beam connections.

Common Uses:

-

Combined high and low beam headlights.

Features:

-

Dual functionality allows switching between high and low beams with one bulb.

-

Reliable design for steady power delivery to both filaments.

-

Easy to install and widely available for replacements.

Vehicles Commonly Using This Socket:

-

Many motorcycles.

-

Older model cars and trucks, particularly Japanese brands like Toyota and Honda.

-

Some European models as well.

Important Notes:

-

Ensure correct alignment when installing to avoid misdirected beams.

-

When upgrading to LED or HID, check if your kit supports dual-filament operation for H4 sockets.

H7 Socket

The H7 socket is one of the most widely used socket types for modern headlights. It is designed for single-filament bulbs and is commonly found in low beam applications. H7 sockets are compact and provide a reliable connection, making them popular in a wide range of vehicle models.

Design:

-

Single filament.

-

PX26d base with two prongs for power and ground connections.

Common Uses:

-

Low beam headlights.

-

Some fog light applications.

Features:

-

Compact design allows for easy installation in most headlight housings.

-

Known for producing bright, clear light that enhances nighttime driving visibility.

-

Provides stable and reliable performance for low beam applications.

Vehicles Commonly Using This Socket:

-

Many European vehicles, such as BMW, Audi, and Volkswagen.

-

Popular in mid-range sedans, hatchbacks, and some SUVs worldwide.

Important Notes:

-

Make sure to handle H7 bulbs carefully as they are sensitive to oil and moisture, which can affect their performance.

-

When replacing with LED or HID bulbs, check compatibility with the H7 socket to ensure proper fitting and function.

H11 Socket

The H11 socket is specifically designed for single-filament bulbs, commonly used in low beam headlights. It’s a popular choice for modern vehicles, offering a reliable connection and a sleek, compact design. The H11 socket is often found in vehicles that use halogen bulbs but can also support LED or HID upgrades.

Design:

-

Single filament.

-

A wide, flat base with a 9006 style connector.

-

Two prongs for power and ground connections.

Common Uses:

-

Low beam headlights.

-

Fog lights.

-

Daytime running lights (DRLs).

Features:

-

Offers consistent and bright light for optimal visibility.

-

Compact size for easy installation in various headlight housings.

-

Well-suited for use with both halogen and upgraded LED/HID bulbs.

Vehicles Commonly Using This Socket:

-

Many Japanese and American vehicles, including models from Toyota, Honda, Ford, and Chevrolet.

-

Commonly used in SUVs, crossovers, and trucks.

Important Notes:

-

When upgrading to LED or HID, check that your new bulb is compatible with the H11 socket, as different setups may require additional adapters.

-

Be cautious during installation to avoid damage to the prongs or the socket housing..

HB3 (9005) Socket

The HB3, also known as 9005, socket is designed for high-intensity discharge (HID) and halogen bulbs that require a high beam function. Known for its durability and high-output lighting, the HB3 socket is a common choice for vehicles that need powerful headlights. The HB3 socket features a unique design that ensures secure connections and optimal light distribution.

Design:

-

Single filament.

-

9005 base type with a 3-prong connector.

-

Larger size compared to some other socket types to accommodate the higher output bulb.

Common Uses:

-

High beam headlights.

-

Auxiliary lights in some vehicles.

Features:

-

Delivers a bright, intense beam of light ideal for high beam applications.

-

Secure and stable connection for consistent performance.

-

Compatible with both halogen and HID bulbs, making it versatile for various lighting setups.

Vehicles Commonly Using This Socket:

-

Found in many SUVs, trucks, and performance vehicles.

-

Commonly used in models from manufacturers like Ford, Toyota, and Nissan.

Important Notes:

-

Ensure the socket is firmly connected to avoid flickering or malfunction.

-

If upgrading to HID or LED, check for compatibility and consider any necessary adapters or additional wiring.

HB4 (9006) Socket

The HB4, also known as the 9006, socket is designed for low beam headlights and is often used in vehicles requiring a brighter, more focused light for nighttime driving. This socket type is similar to the HB3 but is specifically intended for low beam applications, providing reliable and consistent lighting. The HB4 socket is used in a wide variety of vehicles, offering great versatility.

Design:

-

Single filament.

-

9006 base type with a 2-prong connector.

-

Compact design with a slightly smaller profile than the HB3 socket.

Common Uses:

-

Low beam headlights.

-

Fog lights in certain vehicles.

Features:

-

Provides excellent light focus and clarity for low beam applications.

-

Compact size for easy installation into many headlight housings.

-

Often used in conjunction with high beam setups like the HB3 for dual-beam systems.

Vehicles Commonly Using This Socket:

-

Widely used in vehicles such as sedans, SUVs, and trucks from manufacturers like Toyota, Honda, and Ford.

-

Popular in both domestic and international car models.

Important Notes:

-

Always ensure the correct installation direction for the HB4 socket to avoid improper alignment of the beam pattern.

-

When upgrading to LED or HID systems, ensure that the new bulb is designed to fit the HB4 socket or use necessary adapters for proper fitting.

By understanding the details of each headlight socket type, you can make informed decisions about which one best suits your vehicle’s needs. Whether you're replacing a bulb or upgrading your headlights, knowing the differences will ensure better performance and compatibility.

Now that you’re equipped with the knowledge of each socket type, let’s explore key differences between socket types.

Key Differences Between Socket Types

Headlight socket types vary significantly in terms of design, functionality, and application. Understanding these differences is crucial when selecting the right socket for your vehicle's lighting needs. The key differences primarily lie in the filament configuration, the number of prongs, and the specific purposes each socket serves.

Here are some of the key differences you may observe in general:

1. Filament Type

-

Single filament: Used in high beam or low beam applications, where only one filament is required for operation.

-

Dual filament: Used in systems that require both high and low beam functionality within a single bulb.

2. Base and Connector Style

-

Different sockets come with different base types (e.g., P14.5s, PX26d, 9006) and prong configurations (2-prong, 3-prong) depending on the bulb design.

3. Lighting Functionality

-

Some sockets are designed for high beams, others for low beams, and some for specialized applications like fog lights or auxiliary lights.

4. Compatibility with Bulb Types

-

Some sockets are compatible with only halogen bulbs, while others support upgrades like HID or LED.

Comparison Table

|

Socket Type |

Filament Type |

Common Uses |

Base Type |

Number of Prongs |

Popular Vehicles |

|

H1 |

Single filament |

High beam, fog lights |

P14.5s |

1 |

BMW, Audi, Toyota |

|

H3 |

Single filament |

Fog lights, driving lights |

PK22s |

2 |

Off-road vehicles, SUVs |

|

H4 |

Dual filament |

High & low beam headlights |

P43t |

3 |

Motorcycles, older sedans |

|

H7 |

Single filament |

Low beam headlights |

PX26d |

2 |

European vehicles, sedans |

|

H11 |

Single filament |

Low beam, fog lights |

9006 |

2 |

Japanese & American vehicles |

|

HB3 |

Single filament |

High beam headlights |

9005 |

3 |

Trucks, SUVs, performance cars |

|

HB4 |

Single filament |

Low beam headlights |

9006 |

2 |

Sedans, SUVs, domestic cars |

Summary of Key Differences:

-

Filament Type: H1, H3, and HB3 are primarily used for single-beam systems, while H4 and H7 can handle both high and low beam operations.

-

Base and Prongs: Socket types like H1 and HB3 feature more basic prong designs (1-3), whereas others like H4 have multiple prongs for complex bulb functions.

-

Vehicle Application: While certain sockets like H1 and H7 are typically found in European vehicles, others like HB3 and HB4 are more common in trucks and SUVs.

How to Identify the Right Headlight Socket for Your Vehicle

Choosing the correct headlight socket for your vehicle is crucial to ensure proper lighting performance and safe driving. Using the wrong socket can lead to electrical issues, poor light output, or even damage to the headlight assembly. Here are the steps you can take to identify the right socket for your vehicle.

Importance of Matching Socket Type to Bulb and Vehicle

Matching the correct socket type to the bulb and your vehicle is key for the following reasons:

-

Correct Fitment: Each socket type is designed to fit specific bulb sizes and shapes. If you use the wrong socket, the bulb may not fit properly, affecting the light output or causing it to malfunction.

-

Electrical Compatibility: Sockets are built to handle specific electrical loads depending on the type of bulb (halogen, HID, LED). Using an incompatible socket can lead to issues such as flickering lights, short circuits, or blown fuses.

-

Optimal Performance: Proper socket selection ensures that the bulb performs at its highest potential, providing the necessary brightness and clarity for safe driving.

Steps to Identify the Right Headlight Socket

Here are the steps you could take to identify the right headlight sockets for your vehicle in general:

1. Check the Owner’s Manual or Manufacturer Specifications

-

Owner’s Manual: The first and most reliable place to find socket specifications is your vehicle’s owner’s manual. The manual often includes a section on headlight maintenance, specifying the correct bulb and socket type.

-

Manufacturer Specifications: If you can’t find details in the manual, the manufacturer’s website or a parts catalog can provide precise information about which socket type is compatible with your vehicle model.

2. Check the Bulb Type

-

Inspect the current bulb installed in your vehicle to see if it has any visible markings or part numbers. Compare this with the socket options to determine the exact type.

-

Some common bulb types include H1, H7, H11, H4, HB3, and HB4. The number can give you an idea of the socket type used (e.g., H11 for low beam, HB3 for high beam).

3. Consider the Vehicle’s Year, Make, and Model

-

Socket types can vary based on the age and make of the vehicle. Older models may have different socket designs compared to modern vehicles.

-

Double-check by looking up your vehicle’s specific model on reliable automotive parts websites or consulting with a mechanic.

Signs of Socket Wear or Failure

The headlight socket can experience wear over time, leading to issues with bulb performance. Here are common signs to look out for:

-

Flickering Lights: Flickering headlights can indicate a loose or damaged socket connection. If the socket doesn't provide a secure connection to the bulb, it may cause intermittent lighting.

-

Dim or Non-Functional Bulbs: If your headlight bulbs are not operating at full brightness or have stopped working altogether, the socket may be worn out or corroded. Inspect the socket for any visible signs of damage, such as burned areas or corrosion.

-

Overheating or Smell of Burning: A socket that is overheating or emitting a burning smell is often a sign of electrical problems or poor contact with the bulb. This can lead to potential hazards like electrical fires or damage to the vehicle’s wiring.

-

Visible Damage or Corrosion: If the socket shows signs of corrosion, discoloration, or physical damage, it may no longer make a proper connection with the bulb. This can result in faulty headlight performance and requires immediate replacement.

What to Do If You Notice These Signs

-

Inspect the Socket and Wiring: If you notice any signs of damage or failure, visually inspect the socket for corrosion or melted components. Check the wiring for frays or loose connections.

-

Replace the Socket if Necessary: If the socket is damaged, it’s important to replace it promptly to avoid further damage to your vehicle’s electrical system.

-

Consult a Professional: If you're unsure about how to replace the socket or if there is extensive damage to the wiring or socket, consult a mechanic or auto technician to handle the repair.

How To Replace a Headlight Socket

Replacing a headlight socket is a straightforward process that can often be done by the vehicle owner with a few basic tools. However, it's important to follow the correct procedure to ensure safety and proper functionality.

Here’s a guide on how to replace a headlight socket.

Basic Steps for Replacement

-

Turn Off the Vehicle and Disconnect the Battery: Before starting any work on your vehicle’s electrical system, ensure the engine is off and the vehicle is in park. Disconnect the battery to avoid any risk of electrical shock or short circuits.

-

Access the Headlight Assembly: Open the vehicle's hood and locate the back of the headlight assembly. Depending on your vehicle model, you may need to remove a few screws or clips to access the headlight housing. Refer to your vehicle's owner’s manual for specific instructions.

-

Remove the Old Bulb: Gently twist and remove the old bulb from its socket. Be careful not to damage the socket or wiring. If the bulb is stuck, gently wiggle it or apply slight pressure until it comes loose.

-

Disconnect the Socket: Look for the wiring harness connected to the headlight socket. Carefully disconnect the harness by pressing the release tab or unfastening the clip. This will free the socket from the wiring system.

-

Remove the Old Socket: Once the harness is disconnected, carefully remove the old socket. It may be clipped into place or screwed in, so check the installation method and proceed accordingly.

-

Install the New Socket: Position the new socket into place and connect it to the vehicle’s wiring harness. Ensure that the new socket is securely attached to avoid loose connections. If necessary, use the appropriate screws or clips to secure the socket in place.

-

Install the New Bulb: Insert the new bulb into the socket. Make sure it is firmly seated and twisted into place. Be sure to handle the bulb by its base to avoid touching the glass with your fingers, as oils from your skin can damage the bulb.

-

Reconnect the Wiring and Test: Reconnect the wiring harness to the new socket. Once everything is securely in place, reconnect the vehicle’s battery and turn on the headlights to test the new socket and bulb.

-

Reassemble the Headlight Housing: Once the new socket is working correctly, reassemble any parts of the headlight assembly that you had to remove. Tighten any screws or clips that were loosened during the process.

Safety Tips

-

Work in a Well-Lit Area: Make sure you're working in a well-lit environment, as this will help you clearly see any small parts and connectors.

-

Wear Protective Gloves: Using gloves can protect your hands from electrical components and prevent any oils from getting onto the bulb.

-

Use Proper Tools: Ensure you're using the right tools to avoid damaging any parts of the headlight assembly or socket.

-

Check for Damage: Before installing a new socket, carefully inspect the wiring for any damage. If the wiring is frayed or corroded, it may need to be replaced as well.

When to Seek Professional Help

While replacing a headlight socket is generally a simple task, there are times when you should seek professional help:

-

Complex Wiring Issues: If you notice significant wiring damage or if the socket isn’t properly connecting to the wiring harness, it’s best to have a professional handle the repair.

-

Electrical Malfunctions: If your new socket doesn’t work after installation, there may be an underlying electrical issue. A professional mechanic can diagnose and fix the problem.

-

Limited Knowledge or Confidence: If you're not familiar with automotive repairs or feel uncomfortable working with electrical components, don’t hesitate to reach out to a professional to avoid causing more damage.

As you can see, with the right tools and safety precautions, you can restore your headlights to full functionality. However, if you encounter issues like electrical malfunctions or feel unsure during the process, seeking professional assistance is always a wise choice to avoid potential complications.

Final Thoughts

Having a good understanding of these different headlight socket types is essential for ensuring proper installation and optimal performance of your vehicle’s lighting system. With various socket types such as H1, H3, H4, H7, H11, HB3, and HB4, it’s important to choose the right one based on your vehicle’s design and lighting needs. Each socket type serves specific functions, whether for high beams, low beams, fog lights, or auxiliary lights, and features unique designs that cater to various applications.

By familiarizing yourself with these differences, you can make informed decisions when replacing or upgrading bulbs. This knowledge helps prevent compatibility issues and ensures a stable, efficient lighting system, ultimately enhancing your driving experience.

Whether you’re working on a standard replacement or a lighting upgrade, understanding these socket types will save time, effort, and prevent costly mistakes in the long run.

Key Takeaways

-

Headlight sockets connect the vehicle’s wiring harness to the headlight bulb, ensuring secure power transfer.

-

There are two main types of filaments in bulbs: single filament (for either high or low beam) and dual filament (for both high and low beams).

-

The H1 and H3 sockets are commonly used for focused, single-beam applications like high beams and fog lights.

-

H4 sockets support dual-filament bulbs, providing both high and low beam functions from one bulb.

-

H7 sockets are extremely popular in modern vehicles for low beam applications, offering bright and stable performance.

-

H11 sockets are used mainly for low beams, fog lights, and DRLs, and are compatible with halogen, LED, and HID upgrades.

-

HB3 (9005) sockets are designed for high beam lights, delivering intense brightness ideal for highway driving and dark conditions.

-

HB4 (9006) sockets are suited for low beam applications, often used alongside HB3 in dual-beam systems.

-

When upgrading to LED or HID bulbs, it’s important to ensure compatibility with your existing socket type and use appropriate adapters if needed.

-

Proper installation and socket maintenance are key to avoiding flickering headlights, beam misalignment, and other performance issues.

FAQs

Are headlight sockets universal?

No, headlight sockets are not completely universal. Different vehicles and bulb types require specific socket designs, so always check compatibility with your car’s make and model.

How do I know if my headlight socket is bad?

Common signs include headlights that don’t work even after replacing the bulb, dim headlights, or visible corrosion or damage on the socket.

Can I replace a headlight socket myself?

Yes, replacing a headlight socket is generally a DIY-friendly task. Ensure you use the correct socket type for your vehicle and follow proper safety procedures.

Why do headlight sockets fail?

Headlight sockets can fail due to corrosion, overheating, wear and tear, or using bulbs with higher wattage than recommended.